It can carry large amounts of cargo in terms of volume and weight. A single railway train can carry the equivalent of 80 lorries

Localisation

The Guarda Rail Freight Terminal (TFMG) is located in the Centre region (Beiras region) of Portugal, in the city of Guarda, occupying an area of 29,756 m2 adjacent to Guarda railway station. The Guarda rail freight terminal can receive and dispatch containers, tank containers, swap bodies and general cargo, promoting intermodal rail-road transfers.

On the Other hand, the privileged connection of this terminal with the Port of Leixões generates important synergies that simplify and streamline the entire process of transferring goods, in a true extended gate logic.

The TFMG positions itself as an infrastructure with high potential for attracting cargo, benefiting from its strategic location for the following reasons:

Proximity to Spain and its railway network, thereby serving as an inland gateway for European intermodal connections.

Close proximity to the Guarda Business Initiative Logistics Platform, with nearly direct access to the A23 and A25 highways, and subsequently to the Beira Baixa and Beira Alta railway lines, making this hub a border intermodal logistics centre.

Electrification of the Beira Baixa line between Covilhã and Guarda, the modernization of the Beira Alta Line, and the completion of the Concordância das Beiras. The TFMG is located at the junction of these two important lines.

Potential for receiving larger and heavier trains, enabling the separation/aggregation of goods for the north and south of the country and the entire Iberian Peninsula.

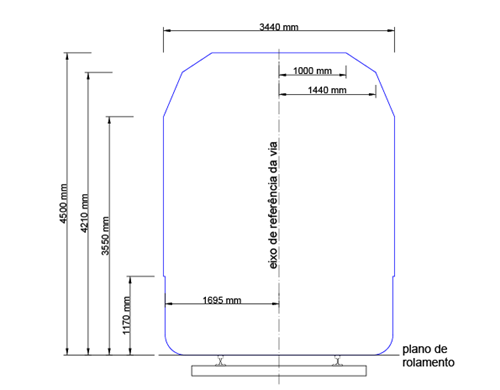

Railway Infrastructure

Useful Lengths of TFML lines

|

Line

|

PK Inicial

|

PK Final

|

Length

|

Usable Length

|

|---|---|---|---|---|

|

A |

206,213 |

206,511 |

282 ml |

181 ml |

|

B |

206,243 |

206,518 |

256 ml |

188 ml |

|

C |

206,243 |

206,518 |

253 ml |

180 ml |